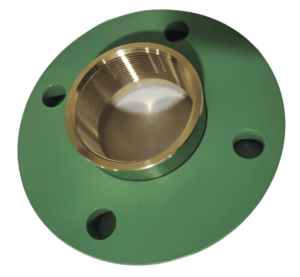

Bimetallic Flange Threaded

Bimetallic Flange Threaded

Bimetallic Flange are engineered components consisting of two different metals bonded together to form a single unit.

Features of Bimetallic Flange Threaded:

Bimetallic Flanges is a composite of three pieces, consists of Carbon Steel ASTM A105, Forged Backing Flanges epoxy coated, brass insert and ABS sleeve. Backing Flanges BS 4505 PN16, Brass Sleeve is suitable for brazing copper tube to BS EN 1057. ABS Sleeve is a thermoplastic Polymer Separates the two pieces (Backing Flange and brass insert) preventing an electric current from passing

Standards & Specifications of Bimetallic Flange Threaded:

The flanges are made to BS EN 1092-3:2003 (BS 4504: Part 3.3:1989) and BS 4504: Part 2:1976 specifications. Solid and composite flanges with nominal working pressures of 16 and 25 in bar gauge (as per chart below) with sockets suitable for brazing joints to BS EN 1254 part 5. Alternate jointing systems suitable to BS 864.2/EN 1254 part 1 for soft soldering up to 67mm OD pipe (DN65) is available. Other systems such as grooved ring, solder ring and press-fit are available made to special orders.

Machining and Finishing of Bimetallic Flange Threaded:

Flange machining dimensions and tolerances are as per Table 10 of BS EN 1092-3:2003 (Clause 10 of Part 3.3) & Clause 6 of BS 4504 Part 2. Copper alloy parts are supplied machine finished. Steel Backing Flange is supplied with machine-finished surface coated with Green Epoxy paint cured at 120 degree C.

Pressure and Temperature of Bimetallic Flange Threaded:

Max. Working Pressure: 232psi (16Bar) Max. Working Temperature: 120C (248F)

Material of Bimetallic Flange Threaded:

- Backing Flange – CS ASTM A105 Epoxy Coating.

- Sleeve – ABS

- Insert – Brass

Optional:

Backing Flange (PN16)- Standard, PN25/ANSI 150/ ANSI 300.