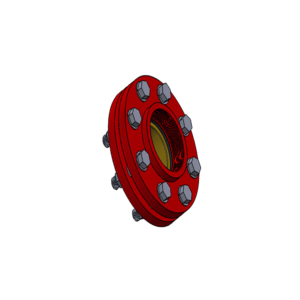

Dielectric Flange – FPT Steel x Brazed With CU

Dielectric Flange – FPT Steel x Brazed With CU

Dielectric Flanges are designed to be installed between pipes of dissimilar metals to avoid electrolysis, which leads to corrosion and pipe failure.

Materials of Dielectric Flange:

- Body Mild steel Flange with Epoxy Coating (Red)

- Tailpiece-Brass

- Insulation-Nylon

- Gaskets-EPDM (Standard), Viton (High Temp.)

Options of Dielectric Flange:

- Body Alloy Steel with Hot dip zinc Galvanized, SS 304 & SS 316

- Tailpiece-Copper

- Insulation-Teflon

- Gaskets- Viton (High Temp.)

Type of Dielectric Flange:

Female Steel x Brazed With CU

Specification of Dielectric Flange:

The Dielectric Flange shall be rated for 250 PSI. Also available of 300 PSI (ANSI 16.39, B 16.42 or B 16.24). The body and nut shall be zinc Galvanized coat, the insulator shall be nylon, the tailpiece shall be brass and the gaskets shall be EPDM RUBBER. Dielectric Flange can be provided with any connection type ( welded, sweat, threaded, etc.) and can be made transition between different pipe size. Also available NPT threading on request.

Features of Dielectric Flange:

Maximum working water pressure 300 PSI. Maximum working water temperature 180°F. Threaded connection-ANSI B 1.20.1, Copper connections – ANSI B 16.22.

Why use Dielectric Flange:

It is use to Electrolytic corrosion occurs in plumbing systems that contain dissimilar metals. Copper present in heating systems is a metal that dissolves very easily. Waterborne copper particles thus circulate in heating network and come in contact with other metals forming an electric pile phenomenon. Water and the two dissimilar metals form a “battery” where electric current carries ions from one metal to another causing it to dissolve.

Application of Dielectric Flange:

Dielectric Flange can be used on all installations of heating, air conditioning, hot water storage tanks, chilled water processing tanks, FCUs and AHUs.

Dielectric Flange’s ordering procedure:

BOSTAN ENGINNERING is Manufacturer for several qualities of Dielectric Flange. To order the Right Dielectric Flange for your particular application indicate that you need a Dielectric Flange specify the model, type, pipe thread size, and coating. An example in included to help illustrate this process.